The shift towards smarter, more connected operations is no longer a distant ideal but a practical necessity. The backbone of this transformation lies in the deployment of sophisticated electrical instruments and devices, which enable industries to optimise processes, increase efficiency, and enhance overall productivity.

Among these essential components, industrial automation hardware solutions for manufacturing industries play a pivotal role in bridging traditional manufacturing with the digital age.

Understanding Industrial Automation Hardware

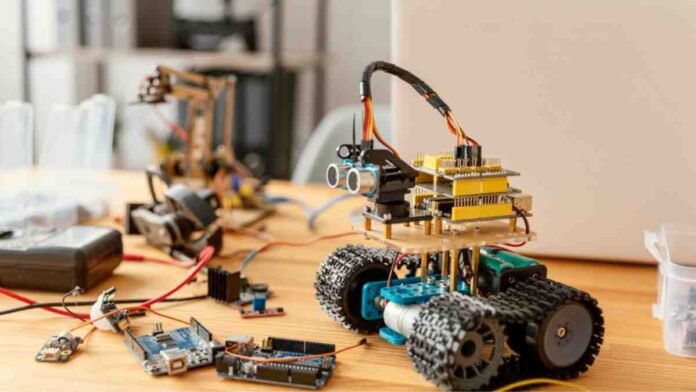

At its core, industrial automation hardware refers to the physical devices and equipment used to control, monitor, and manage industrial processes. This includes sensors, actuators, programmable logic controllers (PLCs), human-machine interfaces (HMIs), and communication modules. Together, these components form the foundation that supports the automation of tasks, from simple repetitive actions to complex system-wide controls.

Unlike manual operations, where human intervention is required at every step, automation hardware allows systems to run with minimal human input. This not only reduces the risk of human error but also ensures consistency and precision in production lines.

Integration in Smart and Connected Systems

One of the most significant advantages of employing automation equipment is the ability to create smart, interconnected systems. Industrial facilities today are evolving into interconnected ecosystems where machines communicate seamlessly, share real-time data, and adapt quickly to changing conditions.

This level of connectivity is possible due to the integration of advanced sensors and communication devices that feed data into central control units. These units then analyse the data and adjust operations accordingly. For example, if a sensor detects a temperature fluctuation, the system can automatically alter cooling mechanisms without manual oversight.

By incorporating such automation hardware, companies gain unprecedented visibility into their operations. This visibility is essential for predictive maintenance, quality control, and energy management, which collectively drive efficiency and cost savings.

Enhancing Efficiency and Productivity

Industrial automation hardware directly contributes to higher efficiency by enabling processes that are faster and more reliable than manual methods. With precise timing and control, production can continue uninterrupted, often around the clock, thereby maximising output.

Furthermore, automation devices reduce wastage by maintaining optimal operational parameters. For instance, automated dosing systems ensure that raw materials are used accurately, which decreases the risk of overuse or spillage.

Automation also facilitates flexibility. Modern equipment can be reprogrammed to accommodate changes in production requirements without the need for extensive physical modifications. This adaptability is crucial in industries where customisation and short product lifecycles are common.

Safety and Compliance

Beyond efficiency, automation hardware significantly improves workplace safety. By deploying devices that handle hazardous or repetitive tasks, the exposure of personnel to dangerous conditions is minimised. For example, robotic arms can perform heavy lifting or operate in environments with harmful chemicals, protecting workers from injury.

Additionally, automated systems maintain thorough records of operational data, which assist in regulatory compliance. Accurate logging of production metrics, safety checks, and maintenance activities ensures adherence to industry standards and reduces the risk of penalties.

Challenges and Considerations

While the benefits are substantial, the integration of industrial automation hardware requires careful planning and investment. Selecting the right electrical instruments tailored to specific operational needs is vital. Compatibility between various devices and systems must be assured to avoid disruptions.

Moreover, skilled personnel are essential to deploy and maintain these systems effectively. Training and ongoing support ensure that equipment functions optimally and that potential issues are promptly addressed.

The Future of Industrial Automation Hardware

The future points towards even greater connectivity and intelligence. Emerging technologies such as edge computing and advanced communication protocols promise to enhance the responsiveness and autonomy of industrial systems. As these developments unfold, automation equipment will become more adaptable, efficient, and capable of self-optimisation.

Organisations that proactively incorporate these advancements into their operations will be well-positioned to meet evolving market demands and maintain a competitive edge.

Benefits of Partnering with Reputable Energy Brands

Incorporating automation hardware often goes hand in hand with optimising energy use. Partnering with established energy providers offers several advantages that complement smart industrial operations. Trusted energy brands bring expertise in efficient power management, ensuring that electrical instruments operate with minimal energy loss.

They also provide reliable support services and customised solutions that align with an organisation’s unique energy requirements. This collaboration helps in reducing operational costs while enhancing sustainability efforts, a growing priority in today’s industry.

Furthermore, reputable energy partners assist with compliance related to energy regulations, helping businesses avoid fines and maintain good standing with authorities. Their experience in deploying energy-efficient systems can accelerate the adoption of cutting-edge automation hardware, enabling seamless integration and long-term reliability.